Cutting-edge R&D

Make kids happier and healthier.

OEM/ODM Manufacturing

Make your unique toys in bulk.

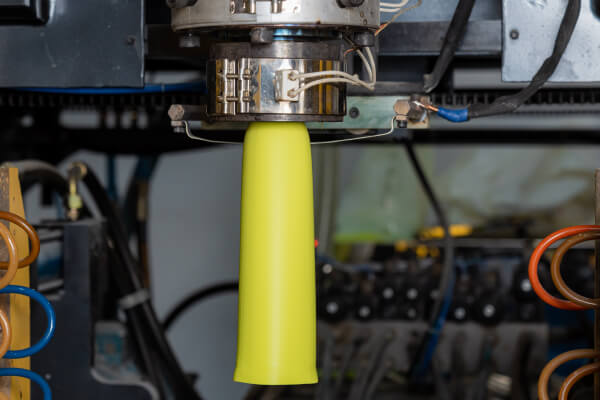

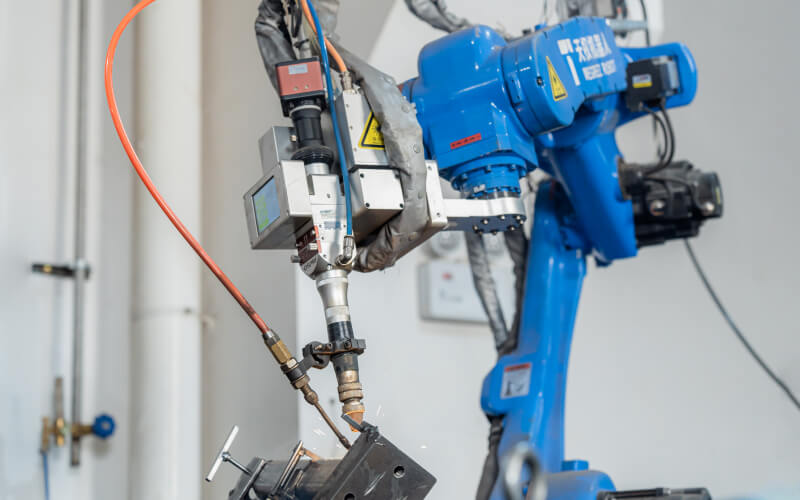

Lean Manufacturing

All fabrications are under one roof.

Quality Management

Make kids happier and healthier.

Considerate Services

Make purchasing easier, faster, and safer.

Precise Cost Control

Make you earn more at every stage.